Aluminum and Stainless Steel are two of the most common metals and also commonly used in CNC machining. It can be said that we use or contact CNC aluminum parts or Stainless steel parts almost every day. When we compare them, many people do not understand what the difference is. In this article, I will introduce in detail the difference between aluminum and stainless steel. Surprisingly, these two materials have different characteristics. So, if you want to know the difference between aluminum and stainless steel, please take a look.

Appearance

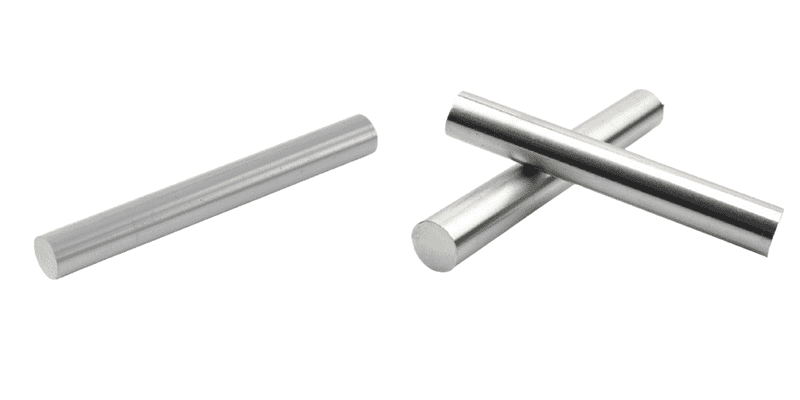

Aluminum and Stainless steel look almost the same, but they look slightly different. As a feature, aluminum has a whitish luster, and stainless steel has a mirror-like shine. It’s hard to understand even if you say it. So please compare it by looking at the image below.

By doing this, you can see the difference in appearance between aluminum and stainless steel. However, please note that the gloss may change depending on the compounding agent.

In addition, well-polished aluminum reflects infrared rays, ultraviolet rays, electromagnetic waves, and various heat rays well. The higher the purity of aluminum, the better this property.

HARDNESS

Aluminum and stainless steel are similar in appearance, but stainless steel is harder than aluminum. Stainless steel is said to be stronger than iron because it does not have the phenomenon of “yield” that suddenly weakens when it receives a certain amount of pressure when it continues to receive pressure.

Also, aluminum is more easily scratched than stainless steel. It is also affected by external force, so if you apply a large force or handle it roughly, it is likely to be deformed by denting or bending. In that respect, stainless steel is strong, so it is often used under conditions where durability is required.

If you are looking for durability, you should choose stainless steel products rather than aluminum products.

WEIGHT

Regarding the weight of stainless steel and aluminum, aluminum is lighter than stainless steel. If you actually express it numerically …

• Stainless steel: 0.764 to 0.806

• Aluminum: 0.264 to 0.284

As you can see, stainless steel is more than twice as heavy as aluminum. If you are concerned about the weight of a frying pan, you should buy an aluminum frying pan.

RUST RESISTANCE

Aluminum is easier to rust than stainless steel. However, both aluminum and stainless steel are said to be materials that do not easily rust. Stainless steel is an alloy of iron (Fe) and chromium (Cr), and is officially called stainless steel, which means “rust-free steel”. However, that doesn’t mean stainless steel is totally rustproof.

Explaining stainless steel in detail, the main component is iron, but by adding chromium, an oxide film is formed on the surface, which protects the inside and makes it less likely to rust. Even if the oxide film is damaged, the surrounding chromium instantly binds to oxygen and repairs the oxide film, making it resistant to rust again. It is this regenerative power that makes stainless steel a more resistant material to rust.

Not limited to stainless steel, the difference between a metal that easily rusts and a metal that does not easily rust is whether the metal has a high or low ionization tendency, and the metal with a higher ionization tendency is more likely to rust.

EASE OF PROCESSING

Aluminum is relatively easier to process than stainless steel. The reasons are mainly as following.

Aluminum is light and strong and conducts electricity well. Most of the aluminum generally used for machining is not pure aluminum, but various properties are given by combining aluminum with other elements. They are called aluminum alloy.

Aluminum alloys are used in a wide range of applications because they can easily produce paper-thin foils and extruded profiles with complex shapes. Aluminum is also easy to plasticize and can be formed into a variety of shapes. Since it has excellent machinability, it is used for tools such as dies and machine parts.

Aluminum also has the property of having a low melting point. For this reason, even if it is melted, the surface is covered with an oxide film, which makes it difficult to absorb gas. Because of its good flow of hot water, aluminum can be used to make thin-walled castings and castings with complicated shapes.

COST

Aluminum is also excellent in cost performance. Compared to other metals, aluminum is less corrosive and has a lower melting point. It is possible to melt and recycle used aluminum products.

For this reason, the energy required to make recycled bullion is only 3% compared to new bullion. It can be said that it is an environmentally friendly and economical material.

Stainless steel is actually classified as a difficult-to-cut material. Unlike aluminum, the low thermal conductivity of aluminum makes it difficult for the heat generated during cutting to escape. This puts more stress on the tool, causing it to wear out more rapidly.

Stainless steel is also a material with high work hardening properties, so machining stainless steel shortens tool life. Work hardening is a phenomenon in which a metal becomes harder than usual when it is processed.

In addition, because of its high affinity with tools and the tendency of chips to weld to the cutting edge, “chipping” occurs, where the cutting edge of the tool or cutting edge is chipped into small pieces. As a result, it is a material that inevitably reduces machining accuracy. It should be careful when machining stainless steel.

WELDING

As for welding, aluminum is more difficult than stainless steel because it is affected by thermal conductivity and oxide film (passivation film). Generally, when machining, aluminum tends to accumulate heat, which can have a negative effect on the chips and blades.

THERMAL CONDUCTIVITY

Aluminum is known as a material with good thermal conductivity, but stainless steel is not a good thermal conductor.

Aluminum is also used for pots and pans in our daily life, but this is because of its tendency to heat up easily. On the other hand, the thermal conductivity of stainless steel is lower than that of aluminum, but in other words, it can be said that heat does not escape easily.

MAGNETIC

Aluminum is usually not magnetic, but there are some types of stainless steel that are magnetic depending on the blending structure. Aluminum is a non-magnetic material and is not affected by magnetic fields, so it can be used to make parts and products that should not be affected by magnetism, so non-magnetic materials are not necessarily bad.

CONDUCTIVITY

Copper, which is used for electric wires, is generally known as a material with high conductivity, but aluminum also conducts electricity well. Stainless steel, on the other hand, is an electrical conductor, but it does not conduct as much as aluminum.

Conclusion

As a summary, Aluminum is softer and lighter than stainless steel. Compared to stainless steel, aluminum is more susceptible to rust. In terms of appearance, aluminum has a whitish luster, while stainless steel has a mirror-like shine. Aluminum is easier to machining with and is more cost effective.