Managing a fleet of vehicles in today’s world feels like a high-stakes puzzle. You have more vehicles on the road, stricter compliance rules, and higher expectations than ever before. It’s a constant juggle of preventive maintenance, repair orders, parts inventory, and technician schedules, often across multiple locations.

If you let any of those pieces drop, you’re looking at costly, unnecessary downtime. According to a recent report from Verizon Connect, over 32% of fleet managers name vehicle downtime as their number one challenge.

That’s why so many businesses are ditching the clunky spreadsheets and paper files for modern digital tools. A Fleet maintenance CMMS (Computerized Maintenance Management System) gives your teams visibility, automates routine tasks, and keeps your vehicles reliable. These systems bring all your data for trucks, vans, and heavy equipment into one place, cutting down on confusion and creating consistency across the entire fleet.

A great CMMS improves how your operations, maintenance, and safety teams work together. Technicians can update work orders instantly from a tablet or phone, and managers can track key metrics to make smarter decisions.

Key Takeaways

Eliminate Costly Downtime: Transition from messy spreadsheets to a digital CMMS to solve the #1 challenge facing 32% of fleet managers.

Boost ROI by 500%: Leverage automated preventive maintenance schedules to prevent breakdowns and extend vehicle lifespans.

Predict Failures in Real-Time: Integrate telematics data to identify part failures before they happen, moving from reactive to predictive repairs.

Streamline Compliance: Ensure tech-ready safety with digital DVIRs and inspection logs that keep your fleet audit-ready and lower insurance risks.

Optimize Technician “Wrench Time”: Increase productivity by giving teams instant mobile access to service histories, parts inventory, and digital manuals.

Table of Contents

Why Fleet Maintenance Teams Need a Centralised System

Precision is everything in fleet operations. A single missed service or a forgotten inspection can snowball into expensive repairs, breakdowns, or serious compliance violations. Relying on spreadsheets or paper systems just makes these risks worse, as information gets lost, duplicated, or becomes outdated the moment it’s printed.

A centralized CMMS acts as the single source of truth for every maintenance activity. It gives your team instant access to:

- Complete vehicle service histories

- Digital inspection logs

- Real-time work order status

- Up-to-date parts inventory

This eliminates guesswork and dramatically reduces surprise failures. Centralization also boosts collaboration. Your operations team knows exactly when a vehicle will be out of service, and technicians know which jobs to prioritize based on parts availability. This teamwork gets vehicles back on the road faster.

Reducing Downtime With Preventive and Predictive Maintenance

Unexpected breakdowns are one of the biggest budget killers for any fleet. A single vehicle failure creates a domino effect, disrupting schedules, delaying deliveries, and frustrating both drivers and customers.

A CMMS is your best defense, allowing you to build automated preventive maintenance (PM) schedules. These programs trigger work orders based on mileage, engine hours, or time intervals, ensuring routine service never gets missed. According to the U.S. Department of Energy, a well-run preventive maintenance program can deliver a return on investment of over 500%.

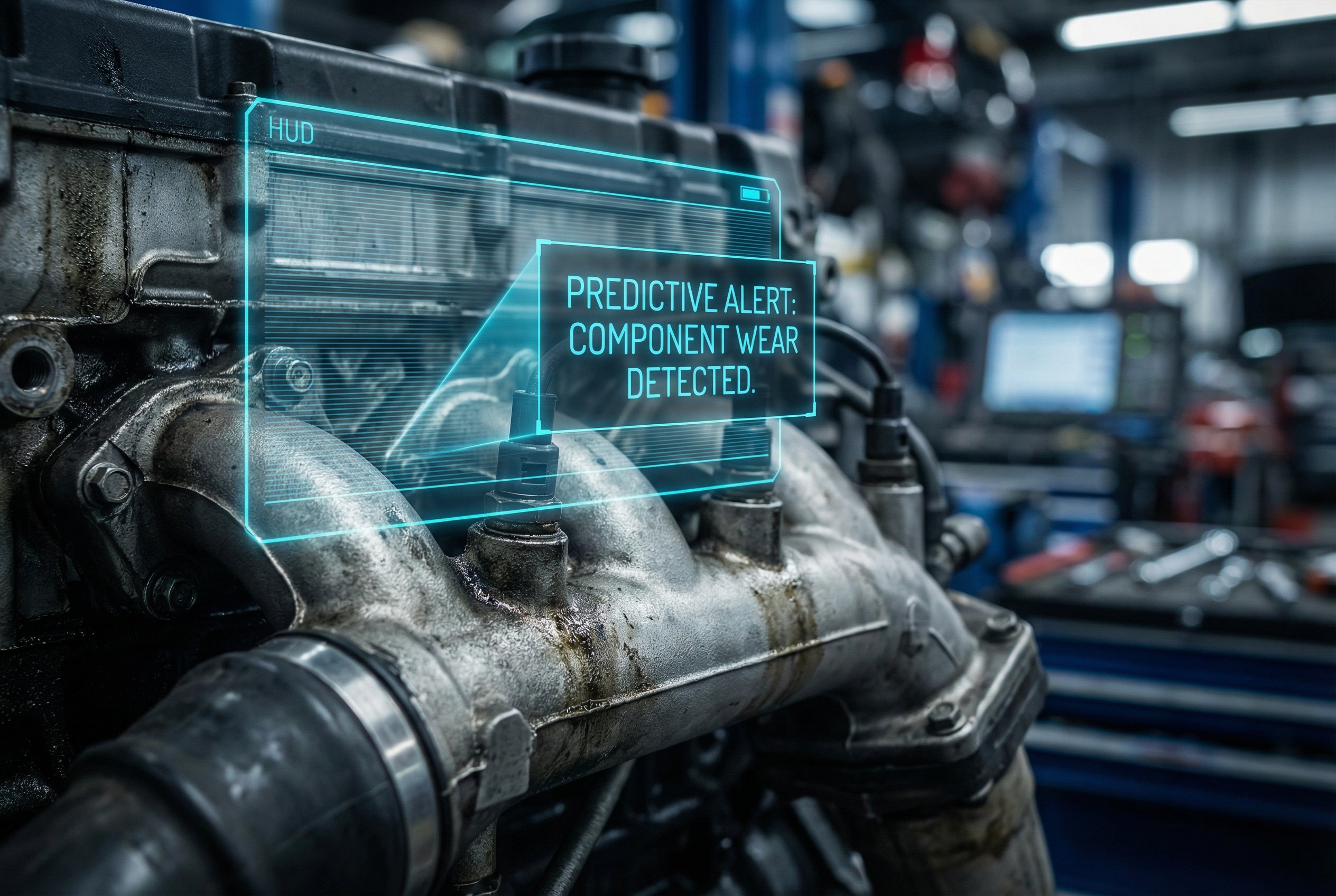

Modern CMMS solutions go a step further by integrating with telematics hardware to enable predictive maintenance (PdM). This is where things get really cool for tech lovers.

Instead of just following a schedule, PdM uses real-time data from sensors to predict when a part might fail. For example, systems like Geotab can monitor Diagnostic Trouble Codes (DTCs), engine temperature, and vibration. If a component shows early signs of wear, the CMMS automatically creates an inspection order before it can cause a breakdown. This proactive approach leads to fewer failures, lower repair costs, and longer vehicle lifespans.

Improving Safety and Compliance Across the Fleet

Safety and compliance are non-negotiable. Regulatory bodies demand perfect records, from inspection reports to service logs. A CMMS makes it much easier to stay organized and audit-ready.

Digital inspection checklists are a game-changer. A driver can complete a full Driver Vehicle Inspection Report (DVIR) on a mobile app. If they flag a problem, like low tire pressure, that report can automatically trigger a work order in the CMMS for a technician to handle. This closes the loop between identifying a problem and fixing it.

This level of documentation is crucial for meeting standards set by organizations like the U.S. Department of Transportation. Specifically, it helps you maintain a good score within the FMCSA’s Compliance, Safety, Accountability (CSA) program, which directly impacts your insurance rates and operational authority.

A well-organized system reduces compliance risks, makes audits less stressful, and builds a stronger safety culture across your entire team.

Enhancing Technician Productivity and Accountability

Your technicians’ time is valuable. Yet, industry studies show that “wrench time,” the period technicians spend actively working on vehicles, can be as low as 30%. The rest is often lost to finding parts, digging up information, or unclear work orders.

A modern CMMS gives that time back. It provides technicians with everything they need on a single screen:

- Real-time access to work orders: No more walking to the office for assignments.

- Step-by-step instructions: Attach digital guides or videos to complex jobs.

- Required parts lists: Know what you need before you start the repair.

- Equipment manuals and diagrams: Pull up the exact schematic for a specific vehicle model.

- Digital signatures and logs: Capture completion details instantly.

With a mobile CMMS, technicians can scan a barcode on a vehicle to see its entire maintenance history, upload photos of a problem, and add notes directly from their device. This keeps managers informed and ensures vehicles get back in service faster.

Streamlining Inventory and Parts Management

You can’t fix a vehicle if you don’t have the right parts. Stockouts cause major delays, but having too much inventory ties up your budget. Financial experts estimate that inventory carrying costs can be as high as 20% to 30% of your stock’s value annually.

A CMMS with inventory management solves this by tracking parts usage in real time. You can set automatic alerts for low-stock items, which prompts you to reorder before you run out. For example, you can set a rule to create a purchase order for oil filters whenever the count drops below 20.

This visibility ensures technicians always have the parts they need, which is essential for efficient service and minimal downtime.

Leveraging Data To Improve Fleet Performance

The best fleet operations are driven by data. A CMMS is a goldmine of information, compiling performance metrics that help you spot trends and make improvements. Some of the most valuable data points include:

- Vehicle downtime frequency

- Maintenance cost per vehicle or per mile

- Mean Time Between Failures (MTBF)

- Parts usage trends

- Technician performance metrics

- Inspection pass and fail rates

These insights help you build better budgets, plan for asset replacement, and optimize your workflows. By analyzing the data, you can identify which vehicles are costing you the most to maintain or which recurring issues are hurting your productivity. According to analysis from firms like McKinsey, fleets that leverage data analytics can reduce their total cost of ownership by 10% to 15%.

Supporting Scalable Operations for Growing Fleets

As your fleet grows, managing it with manual methods becomes impossible. A system that works for 20 vehicles will break down completely when you hit 200. This is where a CMMS truly shines.

Cloud-based CMMS solutions are built to scale. You can add new vehicles, users, or even entire locations with just a few clicks. By standardizing your maintenance processes and centralizing all your information, a CMMS ensures you maintain control and consistency, whether you have one garage or ten. It provides the digital backbone you need to support long-term growth.

Final Thoughts

A well-maintained fleet is the foundation of a reliable, safe, and profitable operation. Modern CMMS solutions empower your teams by automating workflows, tracking performance data, and giving everyone the visibility they need to succeed.

By moving to a centralized digital tool, you not only modernize your maintenance but also ensure your vehicles remain valuable, long-lasting assets that drive your business forward.