Are you a nerd struggling to find cool stuff to do in the Big Apple? Don’t worry – New York City’s got you covered! This concrete jungle is a geek’s paradise, packed with hidden gems and offbeat attractions.

We’ve rounded up 16 awesome nerdy activities that’ll make your inner geek squeal with joy. Get ready to embark on a nerd-tastic adventure through NYC’s geeky wonderland! 3 1 2

Key Takeaways

New York City offers many nerdy attractions like Ripley’s Believe It or Not!, Madame Tussauds, and Gulliver’s Gate Miniature Museum, which are included in the New York Explorer Pass.

Gamers can enjoy venues like Barcade, The Brooklyn Strategist, and The Uncommons, offering arcade games, board games, and over 1,000 tabletop games respectively.

TV and movie fans can take tours like the NYC TV & Movie Bus Tour and the When Harry Met Seinfeld Bus Tour to visit famous filming locations around the city.

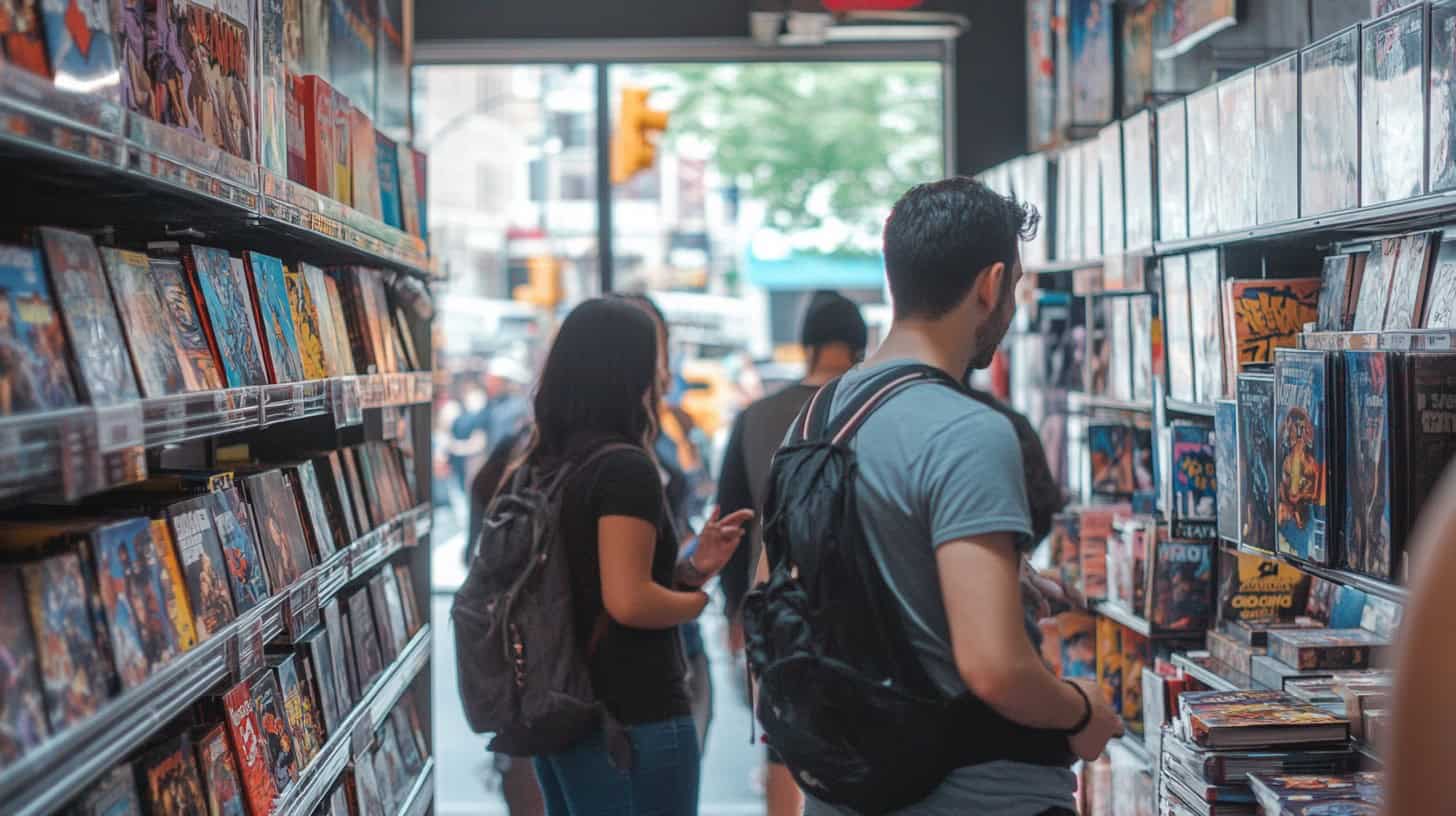

Comic book lovers can shop at Midtown Comics and Forbidden Planet, while toy collectors can explore Toy Tokyo Underground in the East Village.

Major annual events for nerds include New York Comic-Con, a four-day celebration of comics and pop culture, and Free RPG Day at The Compleat Strategist on June 22, 2024.

Table of Contents

Popular Nerdy Attractions in New York

New York City is a nerd’s paradise. From larger-than-life wax figures to mind-bending oddities, the Big Apple’s got it all for the geek in you.

Discover Ripley’s Believe It or Not! in Times Square

Ripley’s Believe It or Not! in Times Square is a geek’s paradise. This odditorium, founded by Robert Ripley, houses a wild collection of bizarre artifacts. You’ll find shrunken heads, a six-legged cow, and even a lock of Elvis’s hair! 2 It’s not just about weird objects, though.

Live performances like “The Incredible Lizardman” and “Nelson Lugo, the Pain-Proof Man” will leave you slack-jawed.

Got a New York Explorer Pass? Great news – your ticket’s included! 1 As you wander through this wonderland of the weird, you’ll spot a piece of the Berlin Wall… right next to some truly head-scratching exhibits.

It’s like stepping into a comic book convention, but way stranger. Trust me, I’ve been there, and it’s an experience that’ll make your inner nerd do backflips.

The strangest things in life are often hidden in plain sight. – Robert Ripley

Explore Madame Tussauds New York

Visit Madame Tussauds New York, where lifelike wax figures bring your favorite celebrities to life. 4 This famous attraction in Times Square offers geeks a chance to get close to their heroes…

well, sort of. From superheroes to sci-fi legends, you’ll find an array of figures that’ll make your inner nerd squeal with delight.

Here’s a tip for fellow geeks: get a New York Explorer Pass. It includes tickets to Madame Tussauds, helping you save some cash for that limited-edition comic book you’ve been eyeing. 3 Plus, you’ll have more time to perfect your pose with Einstein’s wax twin or practice your Jedi mind tricks next to Yoda. It’s a geeky playground that’ll have you grinning from ear to ear.

Visit Gulliver’s Gate Miniature Museum

Gulliver’s Gate Miniature Museum is a mind-blowing playground for geeks who love tiny worlds. It’s like… an entire universe shrunk down to 1/87th scale. 3 You’ll find mini versions of New York’s iconic landmarks, from the Empire State Building to Grand Central Terminal.

But it’s not just NYC – this place takes you on a whirlwind tour of the globe, all without leaving Times Square. 5

Here’s the cool part – it’s included with the New York Explorer Pass. So, you can geek out over the incredible craftsmanship without spending a fortune. From the tiniest trees to the smallest residents, every detail is a feast for your inner nerd.

It’s like being Godzilla for a day… minus the destruction, of course.

Premier Play and Game Venues

Ready to level up your NYC trip? Get your game face on! New York’s got some killer spots where you can roll dice, mash buttons, or strategize your way to victory. From retro arcades to board game cafés, the city’s got something for every type of player – even those into New York state online poker brands.

Game at Barcade

Barcade is a geek’s paradise in New York City. This 21+ hangout mixes classic arcade nostalgia with craft beer goodness. You’re sipping a local IPA while battling pixelated aliens in Galaga.

It’s a bar and a time machine to your misspent youth, with a boozy twist.

At 148 West 24th Street, Barcade is where button-mashing meets brew-tasting. From Pac-Man to pinball, they’ve got all the old-school favorites. 7 And the beer selection? It’s as varied as a comic con crowd.

Barcade: where quarters are currency and high scores are bragging rights. 6

So grab your fellow nerds and head to this gamer’s spot. Just don’t blame us if you wake up with a hangover and carpal tunnel!

Strategize at The Brooklyn Strategist

Calling all strategy buffs! The Brooklyn Strategist is your go-to spot for brain-bending fun. This Carroll Gardens gem offers a treasure trove of board games, from classic favorites to obscure finds.

For just ten bucks, you get four solid hours of gameplay – talk about bang for your buck! 8 It’s like a playground for your mind, where you can flex those mental muscles and outwit your pals.

But it’s not just about the games. The atmosphere at The Brooklyn Strategist is electric. Geeks unite over shared passions, swapping tips and tales of epic victories. You might even stumble upon a tournament or two.

Whether you’re a seasoned pro or a newbie looking to level up your game, this place has got you covered. So grab your thinking cap and head to 333 Court St – your next adventure awaits! 9

Play at The Uncommons

The Uncommons is a board game paradise in Greenwich Village. It’s Manhattan’s first board game café, nestled at 230 Thompson Street. 10 Geeks flock here to dive into a treasure trove of over 1,000 games.

From classic favorites to obscure indie titles, there’s something for every tabletop enthusiast.

Grab a coffee, settle in, and let the games begin! The atmosphere is electric – dice rolling, cards shuffling, and friends laughing. It’s the perfect spot to challenge your crew or make new gaming buddies. 11 Don’t worry if you’re rusty on rules… the staff are game gurus ready to help. The Uncommons isn’t just a café – it’s a portal to countless worlds of strategy, luck, and fun.

Exclusive Nerdy Tours and Experiences

Ready for some geeky sightseeing? NYC’s got you covered! From TV haunts to Broadway secrets, these tours are a nerd’s dream come true. Want to know more? Keep reading!

Join the NYC TV & Movie Bus Tour

Hop on the NYC TV & Movie Bus Tour for a wild ride through the Big Apple’s most iconic filming spots. This tour’s a geek’s dream come true – you’ll see over 40 famous locations from your favorite shows and flicks. 12 From the ghostbusting firehouse to Central Perk’s exterior, it’s like walking through your TV screen.

I’m walkin’ here! – Ratso Rizzo, Midnight Cowboy

Best part? The tour’s included with the New York Explorer Pass. 13 So you can channel your inner Carrie Bradshaw or Jerry Seinfeld without breaking the bank. Next up, let’s dive into another star-studded adventure with the When Harry Met Seinfeld Bus Tour….

Take the When Harry Met Seinfeld Bus Tour

Get ready to relive your favorite New York-based sitcom moments! This tour takes you on a wild ride through the Big Apple’s most iconic TV and movie locations. You’ll cruise past the famous restaurant where Harry and Sally had their unforgettable conversation about…

well, you know. 14 Then zip over to Monk’s Café, where the Seinfeld gang hatched their hilarious schemes. It’s like stepping into your TV screen!

But wait, there’s more! Your ticket’s included with the New York Explorer Pass – talk about a sweet deal. 15 You’ll get to see the actual spots where Kramer practiced his wild physical comedy and where Elaine danced her infamous “little kicks.” It’s a geek’s paradise on wheels.

Just don’t yell “These pretzels are making me thirsty!” at random passersby… or do. We won’t judge.

Enjoy the Hamilton Happy Hour Tour

Step into Alexander Hamilton’s era with a boozy twist! The Hamilton Happy Hour Tour is perfect for history fans and cocktail enthusiasts. You’ll visit taverns that Hamilton frequented, enjoying drinks inspired by the Founding Father himself.

It’s like a pub crawl through the 18th century… but with better hygiene. 16

This tour’s not just about having a few drinks. You’ll get the inside scoop on Hamilton’s life in NYC, from his rise to power to his infamous duel. And hey, your New York Explorer Pass covers the tickets! So raise a glass to A.

Ham – where it happened, how it happened, and with a buzz to boot. 3

Top Geeky Shopping Destinations

Calling all comic book lovers and action figure collectors! New York City’s got some sweet spots for geeky shopping. From rare comics to limited-edition figurines, you’ll find treasures that’ll make your inner nerd squeal with joy.

Shop at Midtown Comics

Midtown Comics is a geek’s paradise in the Big Apple. With multiple locations scattered throughout NYC, this comic book haven offers a treasure trove of graphic novels, action figures, and pop culture memorabilia.

It’s not just about the latest issues – Midtown Comics hooks you up with sweet deals too. Snag pre-orders and daily specials at up to 50% off… talk about a superhero-sized bargain! 17

Step into any Midtown Comics store, and you’re transported to a world where superheroes reign supreme. From rare back issues to the hottest new releases, they’ve got it all. The staff? Total comic book gurus who can chat your ear off about everything from Batman to Saga.

It’s like Comic-Con every day, minus the cosplay (though no one’s stopping you). 18

Find Treasures at Forbidden Planet

Moving from Midtown Comics, let’s venture into another geek paradise. Forbidden Planet is a treasure trove for pop culture enthusiasts. This iconic store has been a mecca for comic book lovers, sci-fi aficionados, and collectors since 1981. 19

Step inside, and you’re transported to a world of endless possibilities. Shelves upon shelves of comics, graphic novels, action figures, and collectibles await your eager eyes. It’s easy to lose track of time as you browse through rare editions and limited-release items.

The staff? They’re walking encyclopedias of geek knowledge, always ready to chat or help you find that elusive piece for your collection. Oh, and here’s a pro tip: if your haul exceeds $80, you’ll snag free shipping on domestic orders.

Talk about a win-win for your wallet and your inner nerd! 20

Explore Toy Tokyo Underground

Toy Tokyo Underground is a geek’s paradise tucked away in the East Village. This basement-level shop at 91 2nd Ave is crammed with collectibles, action figures, and rare Japanese toys. 22 It’s a treasure trove for pop culture enthusiasts and ranks #206 among NYC’s shopping spots. 21

Step into this nerd nirvana, and you’ll find shelves packed with Funko Pops, vintage Godzilla figures, and limited-edition anime merch. The staff knows their stuff – they’re as passionate about these plastic wonders as you are.

Just be warned: your wallet might take a hit, but your inner child will do a happy dance. 21

Unique Nerdy Activities in NYC

Ready to level up your NYC adventure? Dive into these offbeat activities that’ll make your inner geek squeal with joy. From immersive theater to secret superhero lairs, the Big Apple’s got some tricks up its sleeve for the nerdiest of visitors.

Experience Sleep No More

Step into a haunting world of mystery at Sleep No More. This immersive theater experience turns Shakespeare’s Macbeth on its head. You’ll wander through a sprawling five-story “hotel,” encountering eerie scenes and shadowy characters.

It’s like being inside a living, breathing film noir. 23

Masked and silent, you’re free to explore at will. Follow a character, rifle through drawers, or simply soak in the atmosphere. No two experiences are alike. The attention to detail is mind-blowing – from the musty smell of old books to the pulse-quickening original score.

It’s a sensory overload that’ll leave you buzzing long after you’ve left the building. 24

Discover A Local’s Guide to Geek Culture in New York City

New York City’s geek culture is a treasure trove waiting to be unearthed. Local guides offer insider tips on hidden gems that’ll make any nerd’s heart skip a beat. From secret comic book shops tucked away in East Williamsburg to retro arcades serving up classic games and craft beers, these tours dive deep into the Big Apple’s geeky underbelly.

You’ll discover spots where sci-fi authors penned their masterpieces and cafes where cosplayers gather for epic board game nights. 25

But it’s not just about the places – it’s about the people. These guides introduce you to the city’s vibrant geek community. You might bump into indie game developers at The Uncommons or chat with aspiring filmmakers near the Fuller Building.

They’ll show you where to find the best deals on rare action figures and point out locations from your favorite TV shows. It’s like having a nerdy best friend show you around town.

Next up, let’s explore another geeky activity that’ll tickle your fancy. 3

Visit The Compleat Strategist for Gaming

The Compleat Strategist is a gamer’s paradise tucked away in the Big Apple. This gaming mecca has been dishing out dice, cards, and miniatures for nearly five decades. 26 It’s like stepping into a time machine that’s also a treasure chest of tabletop delights.

From classic board games to the latest role-playing adventures, they’ve got it all.

Mark your calendars, fellow nerds! On June 22, 2024, The Compleat Strategist is hosting “Free RPG Day.” 27 It’s a chance to snag some freebies and dive into new worlds without spending a dime.

Whether you’re a seasoned dungeon master or a curious newbie, this event is your golden ticket to level up your gaming experience. Don’t miss out on this epic quest!

Major Annual Nerdy Events

Get ready for some epic nerdy gatherings in the Big Apple! From massive comic conventions to superhero supply shops, NYC’s got your geek fix covered… Read on to discover more mind-blowing events that’ll make your inner nerd squeal with joy!

Attend New York Comic-Con

New York Comic-Con is the geek hotspot of the Big Apple. It’s a four-day celebration of comics, anime, and all things nerdy. Imagine cosplay enthusiasts showing off their creations, celebrities signing autographs, and panels that’ll excite your inner fan.

But watch out, fellow nerds – tickets are selling fast! With only 72 days left, you should grab yours quickly. 28

I’ve been to NYCC, and let me tell you, it’s an amazing sensory experience. The main area is filled with colorful costumes and excited conversations. You’ll find yourself amazed by life-size replicas from your favorite shows one moment, then joining a heated debate about comic book storylines the next.

It’s like Ripley’s Believe It or Not! combined with the Flatiron Building to create a pop culture wonderland. Trust me, you don’t want to miss this nerdy paradise. 29

Explore Brooklyn Superhero Supply Co. (826 NYC)

Brooklyn Superhero Supply Co. isn’t your average store. It’s a secret lair for budding writers and caped crusaders alike. Tucked away in Park Slope, this quirky shop sells everything a superhero might need – from capes to secret identity kits.

But there’s more than meets the eye… Behind a hidden door lies 826 NYC, a non-profit writing center for kids. 30

Open Tuesday through Sunday, 12 to 5, this place is a geek’s paradise. You can stock up on “anti-gravity” or test your powers in their de-villainizing chamber. While you’re there, grab some “canned chaos” or a gallon of “invisible paint”.

The best part? Your purchases support free writing programs for local students. It’s like saving the world, one pen at a time. 31

People Also Ask

What’s the coolest spot for nerds in New York City?

The New York Public Library’s main branch is a geek’s paradise. It’s packed with books and history. Plus, you can see the famous lion statues outside!

Where can I play classic arcade games in the Big Apple?

Head to Astor Place for a blast from the past. You’ll find a bunch of old-school games there. It’s like stepping into a time machine!

Are there any sci-fi attractions in NYC?

You bet! Check out the Unisphere in Queens. It’s a massive steel globe that looks straight out of a space movie. Perfect for your Instagram feed!

What’s a must-see spot for TV buffs?

Don’t miss the Museum of Television and Radio. It’s a treasure trove of TV history. You might even catch a screening of “Death of Klinghoffer”!

Any tips for saving money on Broadway shows?

Hit up the TKTS booth in Times Square. They sell discounted tickets for same-day shows. It’s a great way to catch a performance without breaking the bank!

References

^ https://www.tripadvisor.com/Attraction_Review-g60763-d1534451-Reviews-Ripley_s_Believe_It_or_Not_Times_Square-New_York_City_New_York.html

^ https://gocity.com/en/new-york/things-to-do/top-10-nerdiest-attractions-in-new-york-city

^ https://www.madametussauds.com/new-york/what-s-inside/

^ https://madhattersnyc.com/blog/small-world-visit-gullivers-gate (2017-04-14)

^ https://m.yelp.com/search?find_desc=Barcade&find_loc=New+York%2C+NY

^ https://www.tripadvisor.com/Attraction_Review-g60763-d13417750-Reviews-The_Brooklyn_Strategist-New_York_City_New_York.html

^ https://www.yelp.com/biz/the-brooklyn-strategist-new-york

^ https://www.tripadvisor.com/ShowUserReviews-g60763-d4861416-r630725213-The_Uncommons-New_York_City_New_York.html

^ https://newyorkpass.com/en/new-york-attractions/TV-Movie-Bus-Tour

^ https://onlocationtours.com/new-york-tv-and-movie-tours/new-york-tv-movie/

^ https://onlocationtours.com/new-york-tv-and-movie-tours/when-harry-met-seinfeld-tour/

^ https://www.viator.com/tours/New-York-City/When-Harry-Met-Seinfeld-Tour/d687-2218HARMETSEIN

^ https://www.tripadvisor.com/ShowUserReviews-g60763-d1847162-r517768700-New_York_City_Tour_Hub-New_York_City_New_York.html (2021-09-16)

^ https://www.midtowncomics.com/

^ https://www.yelp.com/biz/midtown-comics-grand-central-new-york

^ https://www.tripadvisor.com/ShowUserReviews-g60763-d565200-r386678273-Forbidden_Planet-New_York_City_New_York.html

^ https://www.tripadvisor.com/ShowUserReviews-g60763-d10168897-r675917838-Toy_Tokyo-New_York_City_New_York.html

^ https://mckittrickhotel.com/events/sleep-no-more/

^ https://www.punchdrunk.com/work/sleep-no-more-new-york/

^ https://www.cityunscripted.com/travel-magazine/a-locals-guide-to-geek-culture-in-new-york-city (2021-09-22)

^ https://www.thecompleatstrategist.com/

^ https://www.thecompleatstrategist.com/?srsltid=AfmBOooG5y7E9FO4T3R9rNe0ctKVnpyYL9YUBmGiYReKuIH-mdLFbQEm

^ https://www.newyorkcomiccon.com/en-us.html

^ https://www.newyorkcomiccon.com/en-us/about.html

^ https://www.superherosupplies.com/pages/about-us

^ https://826nyc.org/news/welcome-to-826nycs-brooklyn-superhero-supply-co-and-youth-writing-center/